My second Year running the Flying Club has been a Year of challenges

. There is a lot of unfinished busines going on

with the Club that cannot be done on one-year bases.

But I have also been flying a lot with my own

Cessna. As a start I decided to tell You about overhauling an

engine.

In October 15'th last year I was flying around in Lappland and

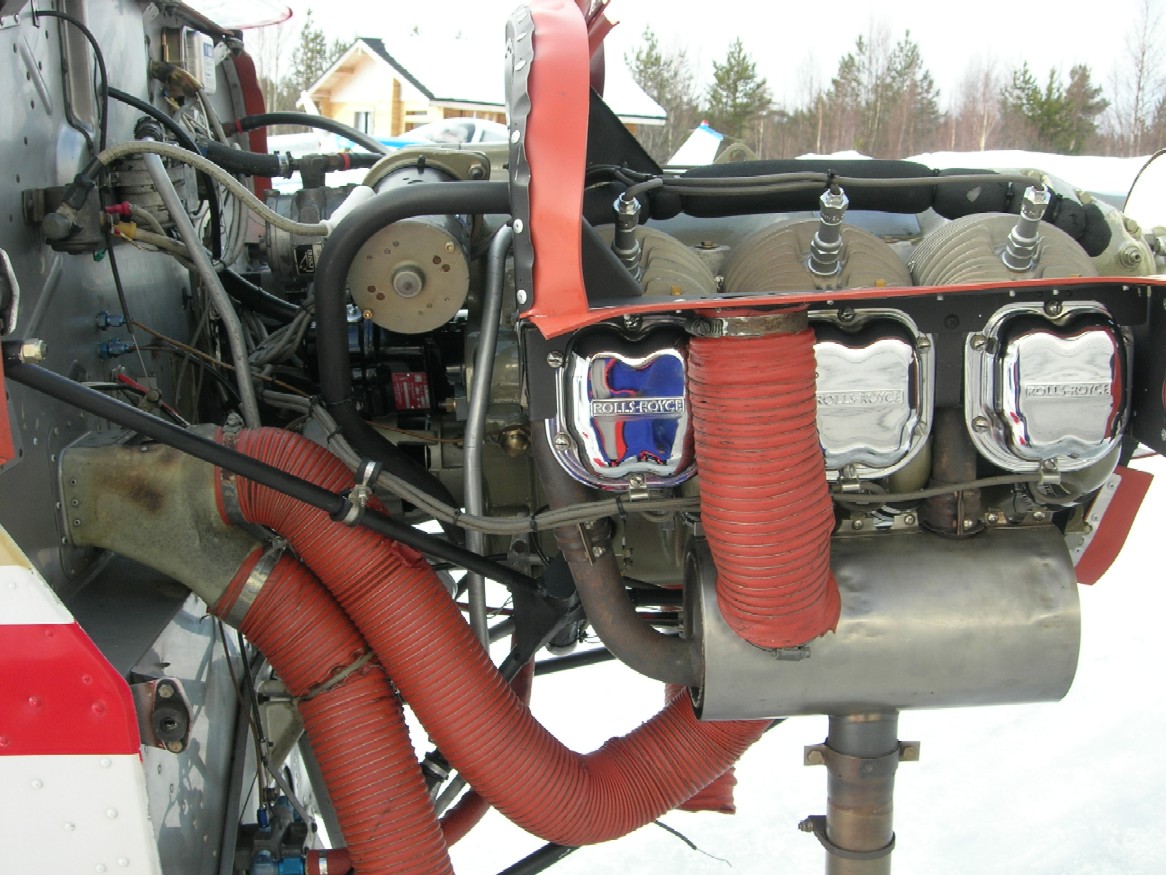

I just coudn't help noticing that my Roll-Royce/Continental

O-300D engine was giving more noices and vibrations than it used to

be. It was still running smoother than Lycoming

but not "silk-smooth" as it used to be . Maybe that was

normal for an engine that has been running 2558 hours SMOH ,

however it still troubled me . I retired last year and for the

first time in my life I had plenty of spare time for the January

2007 . So I decided to ask quotations for an engine overhaul .

I requested Quotations by e-mail from TMC-Continental Factory

New York (www.tmclink.com),

ScanAviation (www.scanaviation.dk)

in Danemark and AirServiceVamrup (www.airservice.dk)

in Danemark.

The Engine Rebuid quotation from the Factory was by far the

most expensive one as you could expect. I studied a couple of

NTSB-reports where a newly rebuild engine had failed . I felt

uncomfortable with those reports and consulted my mechanic

about them . He also felt , that the rebuilding-process gives only

minor extra value for the engine overhaul considering the really

high expences.

ScanAviation gave me a quotation that was slightly more

expensive than the quotation I received from AirServiceVamdrup.

When comparing the quotations I found out that they were

approximately similar and done by the Overhaul Manual according to the

regulations . When I pointed out to ScanAviation by e-mail

that I had received a more affordable quotation from their

competitor , they answered that "they are the best and will

never be the cheapest". Well - Our Flying Club had

a Lycoming

engine overhauled there and we are very satisfied with it. But

Howcome - I have visited ScanAviations Website last year and

this year - always with the result that their website's

Product-page is "under construction". In my opinion they

are too busy if they

have no time to update their website .

AirServiceVamdrup has a website that is top-class : I found out

everything I needed to know and received a quotation in a very

short notice. The Quotation had been edited carefully and the

quarantee for the work was as good as with the others.

My impressions about ASV were positive and I was sure my engine will

be overhauled professionally and with high quality

there . My Mechanic agreed with me - so ASV it was going to be

.

I have had no regrets about my choice . When I delivered the Engine

to Vamdrup I found out that the people were nice and friendly and

the place was exactly as I had imagined it by reading their

website . They promised to e-mail me pictures about the progress

of the overhaul

and that really has happened.

I shall include a photo story about the overhaul :

Sampo Kukkola from ArcticAirService in Ranua

removed the engine and packed it into the trunk of my car for delivery

Me and my wife admiring the engine

The Bridge of the Big-Belt along the way to Vamdrup

Unloading the engine in Vamdrup . To the left

Shop manager Torben Jensen. To the right engine specialist

Vasudavan Iyer Balasubramaniam - better known as "Vasu"

is preparing

for the work

One of the Hangars - take a notice to the

cleanliness and to the highly polished planes

The engine parts removed

The engine parts removed

Pictures taken during the overhaul process

The Engine having its first test run 090207 - and

running perfectly

I left my Home for Engine pickup 190207 via Viking-line from Turku to

Stockholm . I stayed overnight at Vamdrup Hotell ,

which was kindly booked for me by Mr. H.P.Hansen from

AirServiceVamdrup. This time I was in no hurry so I could

take some photos around the Airfield:

In one of the Hangars the Engine was already packed for delivery . We

gathered together for a coffee break and discussed about general

aviation among

else ( there was a big snowstorm approaching Danemark).

"Vasu" gave me instructions for the becoming Engine Break-in

period .

Lifting the engine into my car. From left

Vasu , Me and Mr. Niels Jensen

Vasu transferring the responsibility of the Engine

management to me

I drove then via Sweden to the ArcticAirService - Ranua in

Northern Finland , where I left the Engine to be installed back to the

Plane.

Next Target was my summer Cottage up there in Lappland . The

weather was very fresh when I arrived in the evening 21'th of February.

Temperature was minus 21 degrees and going down. I was lucky to

have plenty of firewood in store for warming up the Cabin . It

slowly

became warmer and warmer inside . However , outside temperature was

minus 28 degrees at night .

Sampo had the Engine installed as we planned 150307.

Me and my Wife arrived to ranua according to the plan during

afternoon 150307 and I sent my wife upstears to Customers lounge

to read books meanwhile

I would take a Test Flight. But as You could guess these big Projects

do not always go as we planned them: Sampo had started the engine

for testing earlier

and found out that it won't idle. So it wasn't ready for test-flight

after all. I called to Vamdrup to Mr. H.P. with my mobile and he handed

the call on to Vasu.

Sampo wasn't very keen on doing anything to the Carburetor because we

might lose the quarantee. Vasu convinced us that we could remove the

carburetor

and clean it. Sampo did as adviced:

Carburetor removed

Sampo cleaning the Carburetor

After installing the Carburetor back the engine

behaved as perfectly as it had been behaving in Vamdrup. Maybe there

were some small inpurities in the

carburetor left from the overhaul-process in the USA

and they flowed to the smallest duct in the Carburetor: the duct that

regulates idling. Next day I called

to Vamdrup and heard that they were so worried about

the situation that they had ordered another overhauled

carburetor from USA in case we can't get

this one fixed. So there it is now in storage

ready for another engine overhaul.

But let's get back to the Test-Flight: There was

an area of freezing rain approaching us from the North, so I had to be

very effective and fast to make the

prefight and one hour test-flight before the rain. I

managed to do that just barely: When I made turns on the north side of

the runway , my windshield got wet ,

but it always dried on the south side. But the actual

test flight was a huge success: I had altitude in use up to

1950 ft and I used average speed of 100 kt

at 70% power( 2450rpm). I made three touch and goes

during which the engine behaved perfectly. During acceleration on ground

at take-off it took

2450 rpm on full power and during taxi idling

was steady. The test Protocoll included notes about many affecting

values, for instance oil pressure was a

steady 60 psi during the test-flight.

My impression from the test-flight was

that the engine was powerful and had a very beautifull sound and all the

annoying noices that harassed me

before were gone.

The Plane parked after the test flight just before

it began to rain

Couple of days later I was able to take a longer test

flight when the weather was better.

I made a lond distance flight to Pudasjärvi and back again and

flew around Ranua to make it a 1,5 hour flight. I had no

difficulties whatsoever. And the

engine sounded great all the time ( I must admit that I use active

LightSpeed Head Phones and the noice level is about the same as inside a

car). I decided

that the plane was ready for a longer flight back home to

south. Me and my wife left Ranua 230307 at noon when the weather was

excellent:

We flew at 4500 ft and had a very smooth ride

We flew over Oulu city at 4500 ft and you can see

Hailuoto island to the right .

It took us about three hours back home but the visibility

decreased and the cloudbase lowered significantly during the last 20

minutes of

the ride. We had a very positive feeling though because the

Overhaul-process had succeeded very well . The engine

behaved just like a new engine should.

Next day I took a one hour flight over our home city Rauma and

found out that the oil consumption had lowered to a minimum - so the

break-in period was

on the better side.

23.05.07 Cessna was at the 25 hour Oil-change service in Ranua.

The old "straight Oil" that Sampo drained out was

considerably clean. The Oil consumption

before the Oil change was next to nothing. Referring to Cessnas

insructions for break-in Sampo and I decided that the Break-in was

done and it was time

to put multi-gear Oil in (15-50W). When I flew back to south that

evening I was very happy with the engine. Altitude changes upwards were

fast and the engine

was very willing to co-operate with me.

One thing that I found out during the break-n Period was that the 100

LL fuel is not the best choice for this engine. It has four times

the Lead-content that

this engine needs . I had to lean all the time except when using full

power. Allways before Magneto-testing I had had to lean for a moment

otherwise the left

Magneto would drop to the limits. The inside of the

Exhaust Pipes was dark grey. When I used Autofuel about 50% mixed with

100 LL before the overhaul

the Magnetos had a 25 rpm drop both steadily and the inside of

the exhaust Pipes were light grey. I am going to mix Autofuel

first about 25% and later about

50% to the 100 LL. The Lead content for the Valves will still

be twice the amount needed. In my opinion this is the way to avoid valve

sticking and besides

lower the expenses. I have the Pedersen Autofuel STC for the plane

and the Engine. ( In Finland Autofuel is 20-30 cents cheaper than 100LL/

litre and the

price of the 100LL is getting considerably higher in Europe next Year).

Tero